Evaluating The Role Of Cylinder Jackets In Enhancing The Printing Quality

In the printing business, the efficiency of the printing press and the clarity of printouts are primary. Cylinder Jackets and ink fountain liners are crucial to optimize the printing process and improve overall performance.

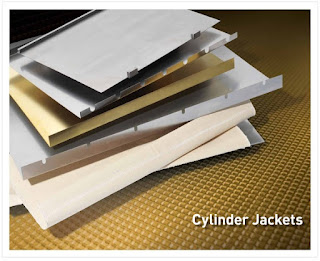

As a standard part, a Printing Machine Cylinder Jacket protects the cylinder in the high-quality sheet-fed Offset printing presses, absorbing minor damage during printing. An impression cylinder jacket can be made of special materials such as brass, plastic, or stainless steel.

The ink fountain is another critical component of offset printing presses. It retains the ink used in printing and controls the ink supplied to the plates, thus optimizing the ink distribution process and maintaining print quality on the final paper.

Ink fountain liners' smooth surface reduces ink wastage, avoiding ink accumulation, spilling, and emulsification. As a result, controlled ink flow produces sharper final images and clearer text on the printed materials.

How Do Cylinder Jackets Work In The Printing Press?

Printing Machine Cylinder Jacket are explicitly used in offset lithography, a printing method that involves transferring ink from a plate to a rubber blanket onto the printing surface.

Cylinder jackets act as protective covers for the printing cylinders, safeguarding them from wear and tear, thus extending their lifespan. The constant friction and pressure involved in the printing process can lead to cylinder damage. This causes poor print quality and increased downtime for maintenance. By implanting cylinder jackets, printing companies significantly reduce cylinder damage. Additionally, it ensures consistent and precise print results over long periods.

Read Also: Enhancing Print Quality And Efficiency With Ink Fountain Liner

The even distribution of heat across the cylinders is crucial for preventing ink from drying too quickly or unevenly. Cylinder jackets are greatly helpful in maintaining a stable temperature during printing. Thus, printing presses using cylinder jackets experience reduced ink wastage and enhanced overall printing efficiency.

Reasons Why To Choose The Combination Of Best Cylinder Jacket And Ink Fountain Liner For Your Printing Press

When printing presses use Printing Machine Cylinder Jacket and ink fountain liners in combination, they can improve print quality and overall productivity to a great extent.

The prominent benefits of using good quality cylinder jackets and ink fountain liners include:

Consistent Print Results

With cylinder jackets at the rescue of cylinders, printing presses can consistently produce high-quality prints without risking the cylinder and the output quality.

Reduced Downtime

Extended cylinder life and minimized ink fountain maintenance reduce downtime for printing presses. This leads to increased productivity and faster turnaround times for each printing task.

Cost Savings

Less ink wastage and lower maintenance requirements mean significant cost savings in the long run.

Sustainable Printing

By optimizing ink usage and reducing waste, ink fountain liners make printing a more sustainable and environment-conscious approach.

Invest In The Best Components for Long Term Benefits

Investing in cylinder jackets and Ink Fountain Liner can make a difference for printing companies aiming to enhance their printing press performance. These innovative technologies safeguard more critical and expensive components of the offset press besides improving print quality, increasing productivity, and saving recurring costs.

Comments

Post a Comment